re-plate 120/1.5 strengthening solutions

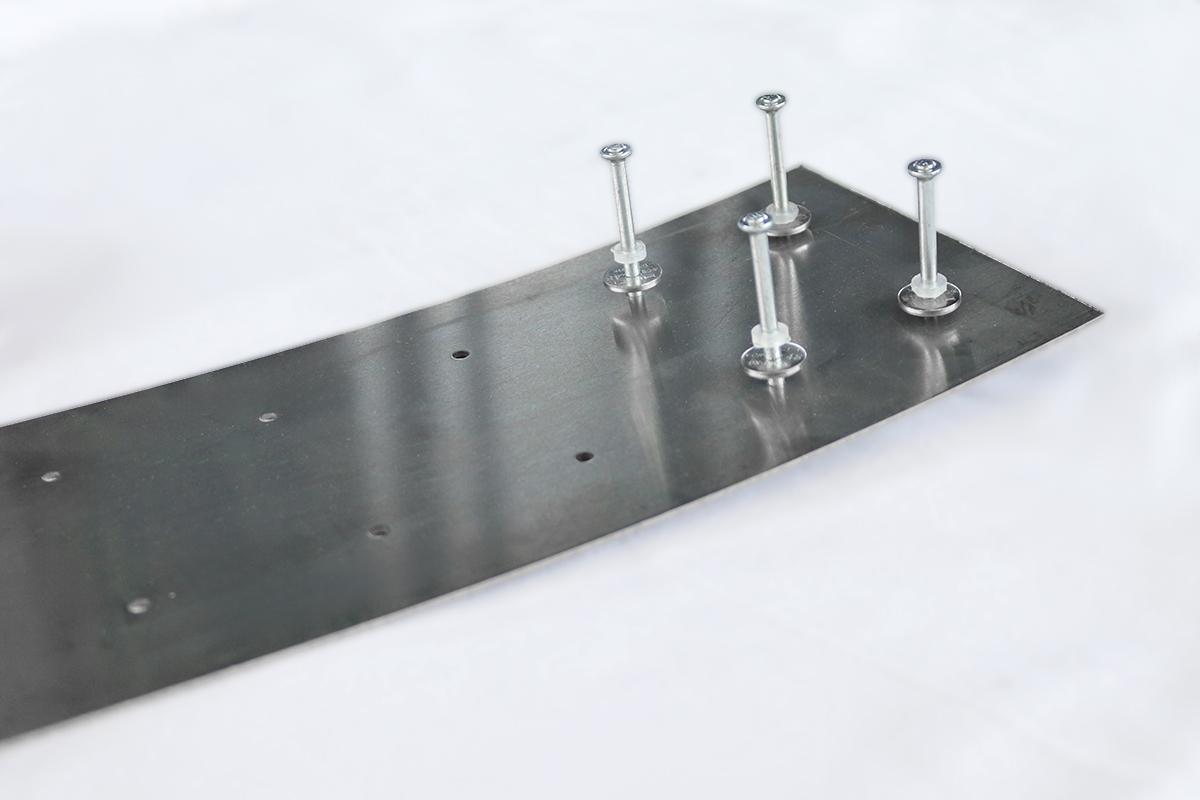

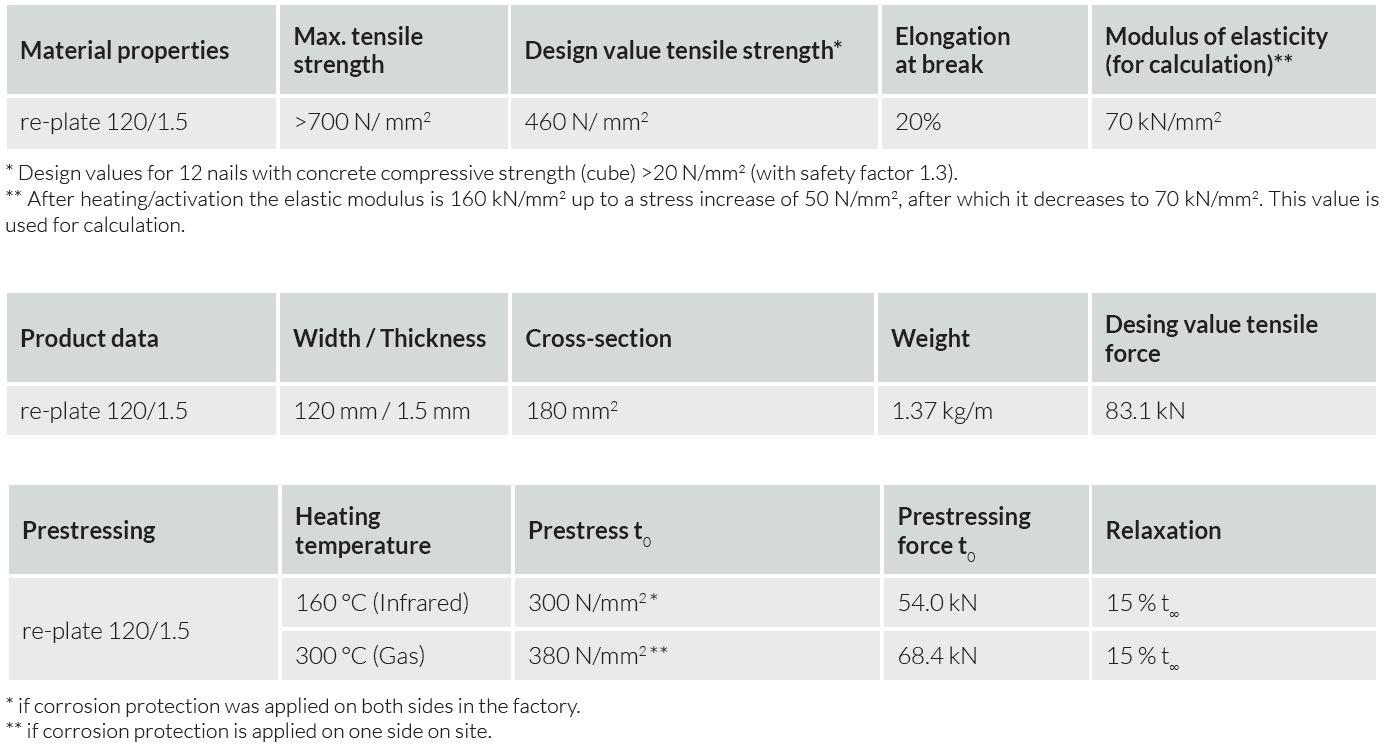

The memory®-steel strip re-plate 120/1.5 is used for minor strengthening of slender concrete slabs in building construction (dry areas indoor, X0 and XC1). re-plate is anchored on both sides and functions as an external, unbonded tension strip. re-plate is elongated in the factory and supplied pre-punched at the ends ready to use on-site. The mechanical end anchorage is composed of a Hilti direct fastening system. For activation of the prestressing, the plate is heated using a gas burner or infrared heater.

Plaster, paint coats and insulation must be removed from the substrate beforehand. re-plate is cleaned on both sides according to the method statement. After the installation and prestressing, re-plate is sealed on all sides with Sikaflex® PRO-3 Purform to prevent water ingress between concrete substrate and the strip. A corrosion protection (Macropoxy® EG-1 Plus, formerly SikaCor® EG-1 Plus) is applied to the cleaned surface on the outside. A corrosion protection on both sides of re-plate is possible. This is already applied in the factory. Learn more

| Advantages |

- Easy-to-install flexural reinforcement for concrete

- Active, instant load-caryying reinforcement (prestressing)

- Minimal space requirement

- Reduction of deflections and crack opening

- Increased performance under service load

- Stress release in the internal reinforcement

| Tested Sika products |

Fire protection:

- SikaCem® Pyrocoat sprayed fire protection mortar

- SikaCem® Pyrocoat Base Sprayed basecoat for the Pyrocoat fire protection mortar

Corrosion protection:

- Macropoxy® EG-1 Plus (former SikaCor® EG-1 Plus) Corrosion protection coating: epoxy-based intermediate coating containing MiO

- Sikaflex® PRO-3 PU joint sealant for bilateral grouting of re-plate

memory®-steel has been tested in systems with Sika fire and corrosion protection products. re-fer gives no guarantee if other mortars and products are used in combination with memory®-steel.

| Combining measures |

Combination of re-plate and Sika® CarboDur®:

re-plate

- Against deflection and cracks in the deck slab and the wall element above

- To relieve load on the existing internal reinforcement

- To cover the loads at serviceability state and under fire

Sika® CarboDur® CFRP-laminates

- To cover the remaining failure load requirement

| Application video |