re-bar 10 & 16 strengthening solutions

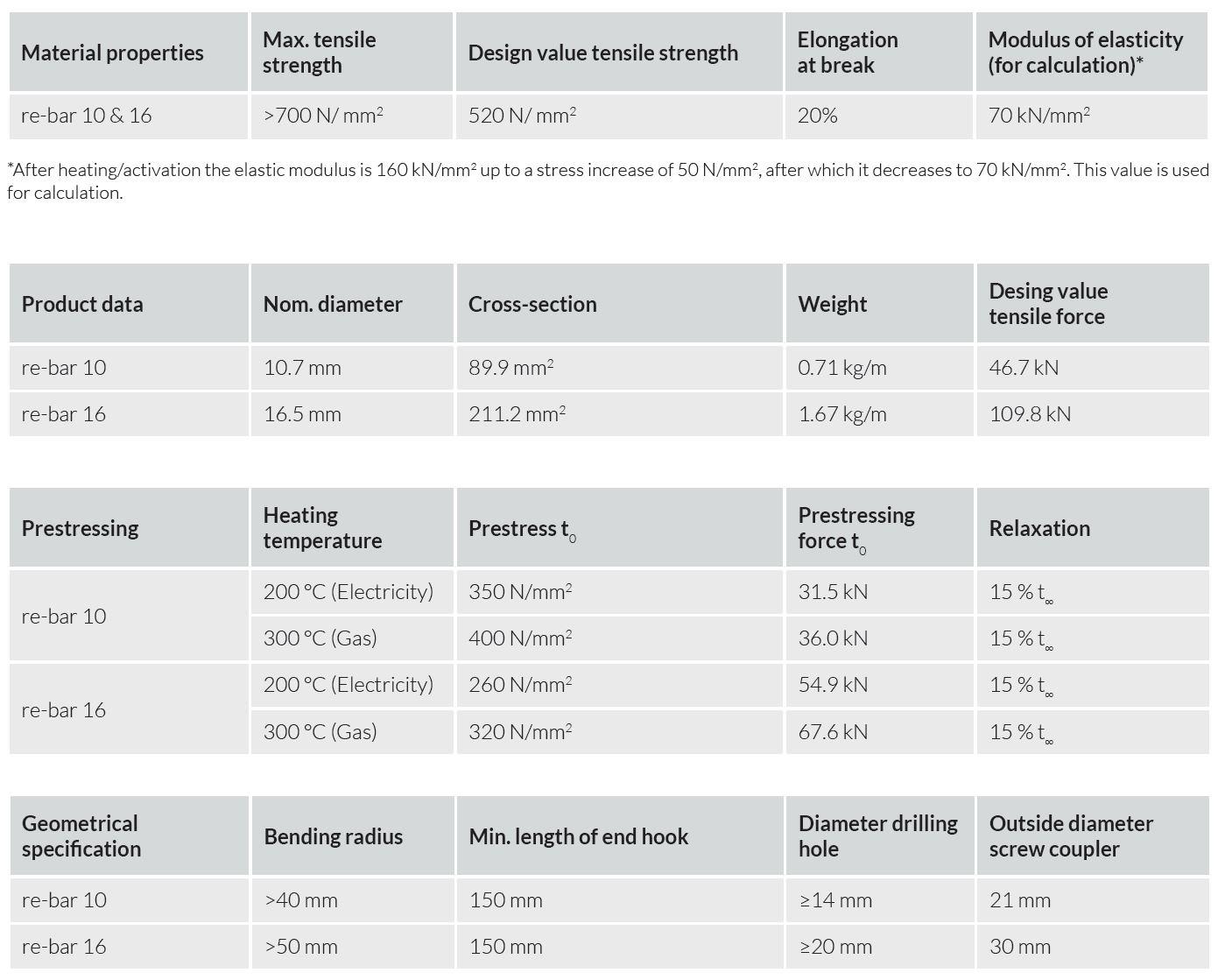

The ribbed memory®-steel re-bar 10 and 16 is used in various fields of structural reinforcement (for concrete and masonry). The bars with a maximum delivery length of approx. 5.8 m are connected with screw couplers and are installed in the desired length. After anchoring in the concrete, re-bar is heated and hence prestressed.

In its final state, re-bar is fully embedded in Sika repair mortar. The bars act as internal prestressing with bond.

To protect against fire, minimum element dimensions and concrete covers are required in accordance with the local standard.

| Advantages |

- Easy-to-install flexural and shear reinforcement for concrete

- Active, instant load-carrying reinforcement (prestressing)

- High ductility (allows joint development and force redistribution)

- Robust anchoring in the intact core concrete

- Minimal space requirement

- Corrosion and fire protection thanks to Sika mortar/concrete cover

- Increases the service life of the structure

- Reduction of deflections and crack opening

- Increased serviceability

- Stress release in the internal reinforcement

- Simple seismic reinforcement of masonry

| Tested Sika products |

Mortars:

- Sika MonoTop® -4052 , shrinkage-compensated, Class R4 repair mortar for horizontal surfaces

- Sika MonoTop® -4010, shrinkage-compensated, Class R4 repair mortar for horizontal, vertical and overhead applications

- Sika MonoTop® -4012, -4080, shrinkage-compensated, Class R4 wet sprayed mortar for overhead and vertical applications

- SikaGrout® -314 N, shrinkage-free, Class R4 precision grouting mortar for formwork holes or cut grooves

- Sika® Rock Gunit BE-8 Dry sprayed mortar (cementitious, alkali free)

Other:

- Sika® AnchorFix® -3030, epoxy adhesive supplied in «cartridge» for anchorage fixings

- SikaTop® Armatec®-110 EpoCem®, corrosion protection and bonding primer

- Sika® FastFix-121 cement mortar for sealing surface cracks

- Sika® InjectoCem-190, very fine cement-based crack injection mortar

re-fer memory®-steel has been tested in combination with Sika sprayed concrete repair and grouting mortars, plus Sika fire and corrosion protection products. re-fer gives no guarantee if other mortars and products are used in combination with memory®-steel.

| Possibilities for anchoring |

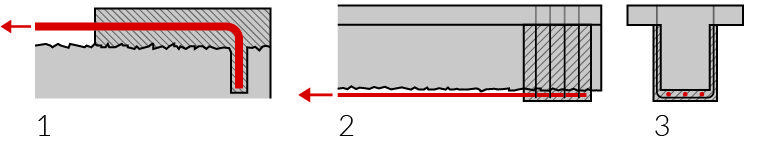

In general, re-bar is anchored behind or at the zero-momentum line for bending reinforcements. For shear reinforcements, re-bar is anchored in the concrete compression zone. The force is transferred via the bond between mortar and concrete subbase. Thanks to the anchoring with end hooks into the core of the concrete, the system is independent of the layer interface bond. This is achieved by bent and glued-in end hooks (1). For narrow concrete beams, the anchoring area can be made more robust with additional stirrups (2, 3). Pre-stressed re-bar shear stirrups are particularly suitable for increasing the shear bond between the mortar and the load-bearing base.

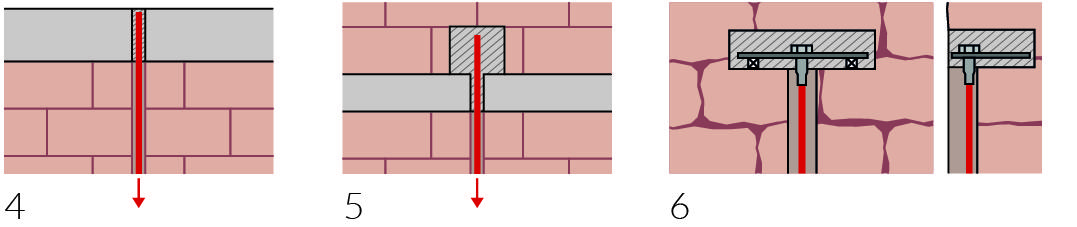

For seismic retrofit of masonry, re-bar must be anchored in the concrete (ceiling, floor slab, concrete base) (4). The anchoring length may not be sufficient for thin ceiling slabs. Additional anchoring can also be carried out above and below the ceiling using concrete blocks (5) or crewed-on end plates (6).

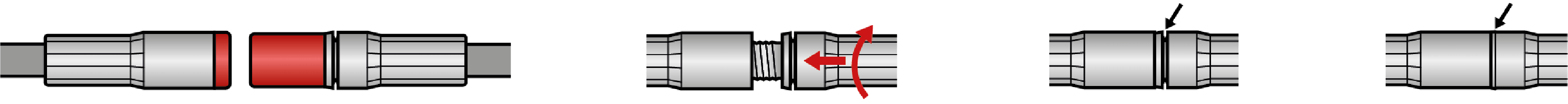

| Screw couplings |

On site, the bars are connected with screw couplers. Protective caps are attached to protect the threads. The joint gap is closed with a wrench.

| Combining measures |

For additional optimisation of the reinforcement systems, the concrete structure can be relieved with hydraulic presses prior to the strengthening measure (1). re-bar is applied, prestressed (2) and embedded into the Sika repair mortar (3).

All re-bar solutions can be combined with fibre-reinforced composites (4) and other reinforcing materials.

| Application video |

Among other things, re-bar can be used to reinforce concrete slabs for bending. The video shows an example of a bridge slab where the centre support has been removed.