| Journals Publications |

Alloy characteristics

Recovery stress formation in FeMnSi based shape memory alloys: Impact of recipitates, texture and grain size.

Arabi-Hashemi, A., Lee W.J., Leinenbach C., Materials and Design, 2018. 139: p. 258-268

FeMnSi based shape memory alloys are considered for engineering applications such as prestressing of concrete or coupling devices. For this, a high recovery stress is desired which forms when the FeMnSi alloy is first elongated and then heated above the austenite transformation temperature under mechanical constraints. In this work, we study the impact of three different microstructural properties on the recovery stress of Fe17Mn5Si10Cr4Ni1(V,C) shape memory alloys: Precipitates, texture and grain size. Precipitates allowed varying the recovery stress in a broad range between 255 MPa and 564 MPa. A recovery stress of 564 MPa was achieved by a combination of a high materials yield strength σ0.1 of 536 MPa and a shape recovery of 14%. The [001] grain orientation with a low Schmid factor has a beneficial impact on the recovery stress due to a higher yield strength when compared with the [011] orientation. A decrease of the grain size caused a Hall-Petch strengthening but had no influence on the recovery stress. However the pseudo-elasticity increased for a decrease of grain size.

https://www.sciencedirect.com/science/article/pii/S0264127517310274

Electrochemical characterizsation and corrosion behavior of an Fe-Mn-Si shape memory alloy in simulated concrete pore solutions.

Lee, W.J., Partovi-Nia R., Suter T. and Leinenbach C., Materials and Corrosion, 2016. 67(8) p: 839-846

The corrosion behavior of an Fe‐17Mn‐6Si‐10Cr‐4Ni‐1(V,C) shape memory alloy was investigated using electrochemical methods with regard to its applications as reinforcing element in pre‐stressed concrete structures. The alloy was tested in three kinds of simulated concrete pore solutions, and open circuit potential and linear polarization resistance were monitored with and without chloride addition. The results were compared with a reference material of conventional structural steel, so called S500 (EN 10149 PT2 standard). It is shown that the shape memory alloy has superior corrosion resistance than the reference material steel S500, and, therefore, can be used as pre‐stressed reinforcing element in concrete without any serious corrosion problem. Several practical issues that can influence the corrosion behavior of the alloy in its use of pre‐stressing reinforcements, such as the effects of strain and surface oxidation by heating, have been also discussed through the electrochemical tests in the simulated concrete pore solutions.

https://onlinelibrary.wiley.com/doi/abs/10.1002/maco.201508701

Development of rolling technology for an iron-based shape-memory-alloy.

Leinenbach, C., Czaderski, C., Michels, J., Graf, M. and Kawalla, R., Materials Science Forum. 2016. p. 79-86.

Low cost Fe-Mn-Si based shape memory alloys (SMA) have drawn much attention during the last two decades as a cost-effective alternative to the expensive Ni-Ti based SMA. In particular, the alloy Fe-17Mn-5Si-10Cr-4Ni-1(V,C) (mass%), which has been developed at Empa shows very promising properties with regard to potential commercial applications in civil and mechanical engineering. This alloy has a higher reverse transformation temperature and larger thermal hysteresis in comparison to the Ni-Ti based alloys, which is adequate for producing stable recovery stresses at room temperature. Furthermore, recovery stresses of up to 300 MPa after heating to only 160°C can be achieved without so-called ‘training’ treatment. Furthermore, the alloy can be easily and cost effectively produced under standard air melting and casting conditions. For availability of these heavily microstructure dependent skills for civil and mechanical engineering, e.g. as prestressing elements in concrete structures or coupling/clamping devices, a process chain for manufacturing is necessary. Therefore, a hot and cold rolling technology for strip production with thermal heat treatment processes was developed at TU Bergakademie on base of experimental simulation results. The last one helps to understand the dependencies of deformation parameters, the deformation behavior and their influence to the microstructure evolution in correlation to the recovery.This paper discusses the basic material properties, recovery stress formation behavior and finally the feasibility of the alloy as reinforcing elements in civil engineering applications by using a rolling technology for flat products.

https://www.scientific.net/MSF.854.79

Recovery stress formation in a restrained Fe-Mn-Si-based shape memory alloy used for prestressing or mechanical joining.

Lee, W.J., Weber, B., Leinenbach.C., Construction and Building Materials, 2015. 95: p. 600-610.

The formation of recovery stresses in a restrained Fe–Mn–Si–Cr–Ni–VC shape memory alloy used for mechanical coupling and prestressing has been investigated with special emphasis on non-ideal restraints that might reduce the recovery stress. The evolution of recovery stresses in the presence of different initial gaps and elastic restraints was investigated experimentally. The results show that the alloy can still produce substantial recovery stresses even under non-ideal restraining conditions. In a second part, the experimental results are analyzed using techniques from constitutive modelling to investigate the evolution of the recovery stress in a more rigorous way. For this purpose the measured strain is decomposed into its elastic, thermal expansion, and transformation parts. With these strain components, the development of the recovery stress during heating and cooling can be described for all different constraint conditions in a unified way. The analysis also shows why optimizing a material for high recovery stress is different from optimizing it for a large recovery strain.

https://www.sciencedirect.com/science/article/abs/pii/S0950061815301197

Phase transformation behavior under uniaxial deformation of an Fe–Mn–Si–Cr–Ni–VC shape memory alloy.

Lee, W.J., Weber, B., Feltrin, G., Czaderski, C., Motavalli, M., and Leinenbach, C., Materials Science and Engineering: A, 2013. 581(0): p. 1-7.

In the present study, the phase transformation behavior of an Fe–17Mn–5Si–10Cr–4Ni–1(V,C) (ma.-%) shape memory alloy is investigated by thermo-mechanical tests with various stress–temperature histories under uniaxial deformation conditions. The stress–strain response and the microstructural evolution of the alloy during deformation at different temperatures reveal that mainly stress induced martensite phases form until the stress level reaches the yielding point for the irrecoverable slip. The reverse transformation occurred mainly within the temperature range of 0‒175 °C. Based on the microstructural and thermo-mechanical analysis, a complete stress–temperature phase diagram for the FCC/HCP transformation of this alloy is presented.

https://www.sciencedirect.com/science/article/abs/pii/S0921509313006266

Thermo-mechanical properties of an Fe-Mn-Si-Cr-Ni-VC shape memory alloy with low transformation temperature.

Leinenbach, C., Kramer, H., Bernhard, C. and Eifler, D., Advanced Engineering Materials, 2012. 14(1-2): p. 62-67.

Fe‐based shape memory alloys are supposed to be an interesting and cost‐effective alternative to NiTi‐based alloys. In this work, the thermo‐mechanical behavior of a novel Fe–Mn–Si–Cr–Ni–VC shape memory alloy produced using standard air‐casting facilities is characterized as well as in the hot forged and cold rolled state. Besides a certain pseudoelasticity, the alloy shows good shape recovery properties and remarkably high shape memory stresses after heating to temperatures of only 160 °C, making the alloy interesting for commercial applications that make use of the shape memory effect.

https://onlinelibrary.wiley.com/doi/abs/10.1002/adem.201100129

A Novel Fe-Mn-Si Shape Memory Alloy With Improved Shape Recovery Properties by VC Precipitation.

Dong, Z., Klotz, U.E., Leinenbach, C., Bergamini, A., Czaderski, C., and Motavalli, M., Advanced Engineering Materials, 2009. 11(1-2): p. 40-44.

In this work, a nominally new Fe‐Mn‐Si based shape memory alloy with a small amount of VC was designed. After an optimized thermo‐mechanical treatment, a shape recovery of more than 90% after an elongation of 4% could be achieved when the alloys were heated up to 225°C. In addition, high recovery stresses of up to 380 MPa could be obtained after heating to 225°C, whereas 330 MPa were obtained after heating to 160°C.

https://onlinelibrary.wiley.com/doi/abs/10.1002/adem.200800312

Mechanical characteristics – memory-steel

Mechanical Performance of Iron-Based Shape-Memory Alloy Ribbed Bars for Concrete Prestressing

Michels J., Shahverdi M., Czaderski C., El-Hacha R., ACI Materials Journal, 2018, 155:

p. 877-886

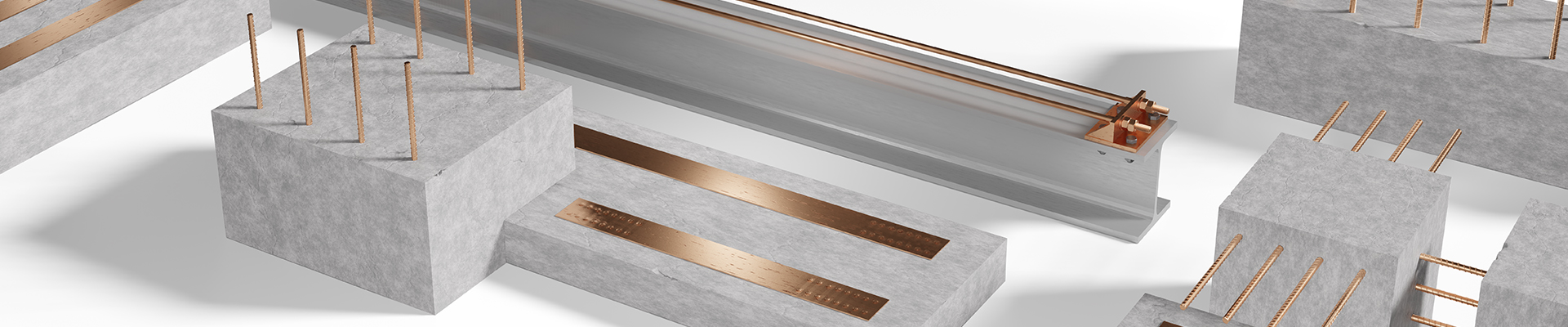

A ribbed bar with a conventional shape and rib geometry as for reinforcing steel but made of a novel iron-based shape-memory alloy (Fe-SMA) is investigated regarding its mechanical performance as a method for concrete prestressing in the field of retrofitting. The alloy has the specific ability to regain its initial shape upon heating at an elevated temperature after having been permanently deformed at ambient temperature. Due to the ribbed surface, the shape recovery of a bar embedded in concrete or other cementitious materials is hindered. Hence, a tensile stress, generally known as the recovery stress, is generated in the bar itself, resulting in a prestress in the concrete. The present campaign aims at demonstrating the main mechanical characteristics of the alloy such as its behavior in tension, possible recovery stresses based on the initially applied prestrain and the subsequent maximum activation temperature, as well as stress relaxation for long-term behavior. Besides the highly ductile tensile behavior, the alloy exhibits prestresses in the range of 250 to 450 MPa (36.2 to 65.2 ksi), depending on the prestraining and activation conditions. Stress relaxation losses in the range of 10% after 1000 hours were observed.

Iron-based shape memory alloy strips for strenghtening RC members: Material behavior and characterization.

Shahverdi M., Michels J., Czaderski C., Motavalli M., Construction and Building Materials, 2018. 173: p. 586-599

Shape memory alloys (SMAs), in the form of bars and strips, can be used as prestressing elements in new reinforced concrete (RC) members or for strengthening existing RC structures, owing to their special characteristic known as the shape memory effect (SME). When the SME comes into play, the material returns to its initial shape upon heating after having been deformed at ambient temperatures. If a return to the initial shape is prevented by mechanical fixation, stress develops in the SMA. A cost-effective iron-based SMA (Fe-SMA) has been developed for application in civil engineering structures. The composition of the developed alloy is Fe–17Mn–5Si–10Cr–4Ni–1(V,C) (mass%). This Fe-SMA exhibits high tensile strength, excellent shape recovery stress (prestress force), and high elastic stiffness. Moreover, its material cost is low and it is easier to manufacture than nickel-titanium (NiTi) alloys. Recently, Fe-SMA strip production has been started at an industrial scale. In this study, the experimentally determined properties of such industrially produced Fe-SMA strips are presented, and their recovery stress and recovery strain have been measured. The effects of prestraining and maximum heating temperature on the obtained recovery stress have been studied. These Fe-SMA strips can be used as external end-fixed reinforcements to strengthen RC structures.

https://www.sciencedirect.com/science/article/abs/pii/S0950061818308559

Iron-based shape memory alloys for civil engineering structures: An overview.

Cladera, A., Weber, B., Leinenbach, C., Czaderski, C., Shahverdi, M., and Motavalli, M., Construction and Building Materials, 2014. 63: p. 281-293.

Iron-based shape memory alloys (SMAs), especially Fe–Mn–Si alloys, are materials that have great potential in civil engineering structures, but their application is still in a pioneer stage. Recent developments in alloy composition and manufacturing envisage new perspectives, especially in the field of repairing structures as well for new structures, when using these SMAs as prestressing tendons. This paper presents the fundamentals of the martensitic transformation from an engineering perspective as well as some key properties, such as recovery stress, corrosion resistance, weldability and workability. Finally, some unsolved aspects are collected, and new perspectives for the use of these SMAs are presented.

https://www.sciencedirect.com/science/article/abs/pii/S0950061814003493

Stress recovery behaviour of an Fe–Mn–Si–Cr–Ni–VC shape memory alloy used for prestressing.

Lee, W.J., Weber, B., Feltrin, G., Czaderski, C., Motavalli, M. and Leinenbach, C., Smart Materials and Structures, 2013. 22(12): p. 9.

This paper describes the stress recovery behaviour of an Fe–17Mn–5Si–10Cr–4Ni–1(V, C) (mass%) shape memory alloy used for prestressing of civil structures. The prestressing due to the shape memory effect was simulated by a series of tests with pre-straining of the material followed by heating and cooling back at constant strain. Different pre-strain and heating conditions were examined. Moreover, the response due to additional mechanical and thermal cyclic loading has been investigated. These results were used to predict the partial prestress loss in a structure due to variable loading during operation. Finally, a heating test at constant strain was performed after the cyclic loading to check the possibility of reactivating the prestress lost during an exceptionally high load.

https://iopscience.iop.org/article/10.1088/0964-1726/22/12/125037/meta

Feasibility of concrete prestressed by shape memory alloy short fibers.

Moser, K., Bergamini, A., Christen, R. and Czaderski, C., Materials and Structures, 2005. 38(279): p. 593-600.

Mortar and concrete exhibit low tensile strengths. Hence, cracks develop easily due to shrinkage and external actions. They can be prevented by applying prestress, thus obtaining crack-free products. Such products exhibit a high bending and tensile strength, are leak proof and of high durability. Prestress can be realized using external or internal wires or cables. In thin walled products, however, this is not feasible. For this purpose, short fibers of shape memory alloy (SMA) wires were embedded in mortar. The wires had been shaped by inelastic elongation into loop-and star-shaped fibers. After hardening of the mortar, the specimens were heated up in order to activate the tensile stress in the fibers, thereby causing a prestress of the surrounding mortar. The effect was monitored by length measurements both on specimens with and without fibers. Compression stresses in the cement mortar were estimated by multiplying the difference in strain between fiber-reinforced and reference prisms by the Young’s modulus. Thus, compression of some 7 MPa was reached in the experiments. For practical applications, alloys with suitable temperature domains of austenitic and martensitic transformation, most likely Fe-based, and efficient methods for the production of such fiber mortars are to be developed.

https://link.springer.com/article/10.1007/BF02479551

Long-term behavior

Stress recovery and cyclic behaviour of an Fe-Mn-Si shape memory alloy after multiple thermal activations.

Hosseini, E., Ghafoori, E., Leinenbach, C., Motavalli, M. and Holdsworth, S.R., Smart Materials and Structures, 2018. 27(2)

The stress recovery and cyclic deformation behaviour of Fe–17Mn–5Si–10Cr–4Ni–1(V,C) shape memory alloy (Fe-SMA) strips, which are often used for pre-stressed strengthening of structural members, were studied. The evolution of recovery stress under different constraint conditions was studied. The results showed that the magnitude of the tensile stress in the Fe-SMA member during thermal activation can have a signification effect on the final recovery stress. The higher the tensile load in the Fe-SMA (e.g., caused by dead load or thermal expansion of parent structure during heating phase), the lower the final recovery stress. Furthermore, this study investigated the cyclic behaviour of the activated SMA followed by a second thermal activation. Although the magnitude of the recovery stress decreased during the cyclic loading, the second thermal activation could retrieve a significant part of the relaxed recovery stress. This observation suggests that the relaxation of recovery stress during cyclic loading is due to a reversible phase transformation-induced deformation (i.e., forward austenite-to-martensite transformation) rather than an irreversible dislocation-induced plasticity. Retrieval of the relaxed recovery stress by the reactivation process has important practical implications as the prestressing loss in pre-stressed civil structures can be simply recovered by reheating of the Fe-SMA elements.

https://iopscience.iop.org/article/10.1088/1361-665X/aaa2c9/meta

Fatigue Behavior of a Fe-Mn-Si Shape Memory Alloy used for Prestressed Strengthening.

Ghafoori, E., Hosseini, E., Leinenbach, C., Michels, J. and Motavalli, M., Materials and Design, 2017. 133: p. 349-362

Cyclic deformation and fatigue behavior of an iron-based shape memory alloy (Fe-SMA) Fe-17Mn-5Si-10Cr-4Ni-1(V,C) were studied. In the first step, cyclic tensile tests were performed to characterize the material’s mechanical properties in tension (elongation at break, yield, and tensile strength) as well as the recovery behavior of the alloy. Furthermore, the effect of strain rate on the cyclic loading tests was investigated. It was observed that the strain rate has a clear influence on the stress-strain behavior of the alloy. In the second step, the fatigue behavior of the alloy after pre-straining and thermal activation under strain-controlled conditions was evaluated. While the stiffness of the alloy remained almost constant during high-cycle fatigue loading, a decrease in the recovery stress was observed, which should be taken into account in design assessments. The loss in the recovery stress was assumed to be mainly a result of a transformation-induced relaxation (TIR) under cyclic loading. Furthermore, this study examines the applicability of a constant life diagram (CLD) model to determine the fatigue limit of the alloy for different stress ratios (R). The existing results of the fatigue tests showed full consistency with the proposed fatigue design criterion. A formulation based on the CLD model was proposed for a safe design of the alloy as a structural pre-stressing element under a high-cycle fatigue loading regime.

https://www.sciencedirect.com/science/article/pii/S0264127517307311

Cyclic deformation and structural fatigue behavior of an Fe-Mn-Si shape memory alloy.

Koster, M., Lee, W.J., Schwarzenberger, M. and Leinenbach, C., Materials Science and Engineering A, 2015. 637: p. 29-39.

In this work, the iron based shape memory alloy (SMA) Fe–17Mn–5Si–10Cr–4Ni–1(V,C) was investigated regarding its behavior under cyclic mechanical loading. In a first series of experiments, cyclic tensile tests were performed to characterize the material properties. In addition, the basic recovery behavior of the alloy such as recovery strain and recovery stress was characterized. Based on the obtained results, cyclic mechanical loading experiments were performed to analyze the structural fatigue behavior of the shape memory alloy with regard to its use for prestressing or coupling elements in civil and mechanical engineering, respectively. The results showed that high to low cycle fatigue transition appears at a stress significantly higher than the elastic limit of the alloy. The results can be used for the appropriate design of Fe–Mn–Si SMA elements under cyclic loading.

https://www.sciencedirect.com/science/article/abs/pii/S0921509315004268

Structural behavior

Experimental study on Fe-SMA-to-steel adhesively bonded interfaces using DIC

W. Wang, A. Hosseini, E. Ghafoori

This study aimed to reveal the interface behavior of iron-based shape memory alloy (Fe-SMA) strips bonded to metallic substrates in order to ensure the integrity of such joints. A series of single lap-shear tests was performed on Fe-SMA-to-steel adhesively bonded joints. The test results reveal that the bond strength can reach over 70% of the tensile strength of the Fe-SMA and the cohesive failure mode can be realized. It is identified that three energy dissipation mechanisms occurred during the debonding process, indicating that the experimentally obtained bond-slip relations represent more than the energy dissipation by the failure of the adhesive.

Paper_Experimental study on Fe-SMA-to-steel adhesively bonded

Iron based shape memory alloys as shear reinforcement for bridge girders

C. Czaderski, M. Shahverdi, J. Michels

Considerable age of a very high number of bridges conjointly with a steadily increasing amount of traffic and changes in design philosophy (e.g. earthquake engineering) have made maintenance needed and retrofitting become more and more important over the years. Retrofitting can become necessary both for

flexure or shear enhancements. Existing steel solutions for shear strengthening are very laborious and complex, and the durability of the steel construction is questionable. As an alternative to steel solutions, carbon fiber reinforced polymer (CFRP) sheets or strips are used for shear strengthening of reinforced

concrete beams. But, prestressing of CFRP sheets or strips is hardly applicable. However, a prestressing of a shear strengthening has the advantages that the width of existing shear cracks can be reduced and the stresses in the internal steel stirrups are reduced. Therefore, in this study, a new iron-based shape memory alloy (‘memory-steel’) in the form of Ushaped (stirrups) ribbed bars with a nominal diameter of 12 mm were used in combination with sprayed

mortar for shear strengthening of reinforced concrete (RC) structures. The memory-steel bars were activated with electric resistive heating. The activation resulted in a prestress of about 300 N/mm2 in the memory-steel reinforcement and consequently in vertical compressive stresses in the web of the RC beams. Large-scale experiments on T-beams with a height of 0.75 m and a total length of 5.2 m were performed to show the practicability and efficiency of the memory-steel shear strengthening. Promising results have shown that the new strengthening system works well in practice. The shear capacity could

be increased significantly. Furthermore, at the serviceability limit state, the prestressed memory-steel stirrups reduced the overall beam deflections, the stresses in the internal steel stirrups, the number of cracks, and the crack widths.

Paper_Iron based shape memory alloys as shear reinforcement for bridge

Iron-based shape memory alloy (Fe-SMA) for fatigue strengthening of cracked steel bridge connections.

Izadi, M., Motavalli M. and Ghafoori E. Construction and Building Materials, 2019. 227: p. 116800.

Smart iron-based shape memory alloys (Fe-SMAs) are used in this study to retrofit fatigue-cracked riveted connections in steel bridges. The prestressed strengthening technique is found to be an effective approach to overcome fatigue-related damage in riveted connections. Because of the property of Fe-SMAs known as shape memory effect, these alloys can be prestressed without difficulty. The activated (i.e., prestressed) Fe-SMA strips (two 50-mm wide × 1.5-mm thick) are anchored to the flanges of a steel I-beam in either side of the connection. Thereafter, a test setup is specifically designed to examine the SMA-strengthened cracked double-angle connections. First, a static test is performed on the unstrengthened connection without any crack. Subsequently, two high-cycle fatigue (HCF) tests are conducted on a pre-cracked connection. The pre-cracked connection with no strengthening is subjected to fatigue loading with a load ratio of R = 0.1. After practically loading cycles, the crack propagates up to 50% of the connection depth, whereas the fatigue crack growth rate gradually decreases because of the reduction in connection rigidity. Finally, the SMA-strengthened connection is subjected to the HCF loading. It is observed that the fatigue life is substantially enhanced, and the fatigue crack is arrested by the activated Fe-SMA strips.

https://www.sciencedirect.com/science/article/abs/pii/S0950061819322305

Thermally activated iron-based shape memory alloy for strengthening metallic girders.

Izadi, M. Hosseini A., Michels J., Motavalli M. and Ghafoori E., Thin-Walled Structures, 2019. 141: p. 389-401.

The study presents a new retrofit solution for strengthening metallic I-girders. The retrofit system involves two iron-based shape memory alloy (Fe-SMA, ‘memory-steel’) strips (each with a width and thickness of 50 and 1.5 mm, respectively) that are mechanically anchored (using friction clamps) to the girders. The shape memory effect (SME) of the Fe-SMA material has been used to activate/prestress the strips by heating to a predefined temperature. The main advantage of the proposed SMA-retrofit system is that, unlike conventional systems, it can prestress itself without a need for heavy hydraulic jacks, which then results in a significant reduction of the required time, labor works and cost of prestressing process. In order to evaluate the efficiency of the proposed retrofit system, in this study, a series of static and fatigue four-point bending tests were performed on a 6.4-m SMA-retrofitted beam. Five static tests were performed on a steel beam with different SMA prestressing levels and included a reference un-strengthened test. The test results indicated that the achieved prestressing levels (i.e., recovery stresses) in the Fe-SMAs for activation temperatures of 100, 160, and 260 °C were approximately 160, 330, and 430 MPa, respectively. The induced compressive stresses in the bottom flange were in the range of 10–30 MPa. It was demonstrated that the Fe-SMAs could be re-activated for multiple times even up to higher temperatures (than the initial activation temperature), which would then result in higher prestressing levels. These features make the proposed SMA-based system a versatile and adaptable retrofit solution. Furthermore, the SMA-strengthened beam with the maximum prestressing level (activation temperature of 260 °C) was subjected to 2 million load cycles with a load ratio of R = 0.2 and a loading frequency of 4.35 Hz. The results of the high-cycle fatigue (HCF) tests showed no slippage in the anchorage system and a stable prestressing in the Fe-SMA members during the tests, which demonstrates the reliability of the proposed system under HCF loading regime.

https://www.sciencedirect.com/science/article/pii/S0263823118314125

A comparative study between Fe-SMA and CFRP reinforcements for prestressed strengthening of metallic structures.

Hosseini, A., Michels J., Izadi M. and Ghafoori E. Construction and Building Materials, 2019. 226: p. 976-992.

In the last two decades, carbon fiber reinforced polymer (CFRP) composites have been used for the strengthening of various civil structures. Since recently, iron-based shape memory alloy (Fe-SMA) has been introduced as a promising material, and Fe-SMA reinforcements have been utilized for prestressed strengthening of existing structures. This study aims to conduct a comparative analysis between the structural performance and cost of using Fe-SMA vs. CFRP reinforcements for the prestressed strengthening of existing civil structures. First, a comprehensive study is presented that compares Fe-SMA and CFRP at the material level, with the main focus on the relevant structural aspects, such as the static tensile behavior, high-cycle fatigue (HCF) performance, creep and relaxation, corrosion resistance, thermal compatibility with common construction materials (i.e., steel and concrete), and the behavior under high temperatures and fire exposure. Second, the application complexity and the structural performance of the two strengthening techniques, by using mechanically anchored prestressed CFRPs or thermally activated Fe-SMAs, are compared at the system level by performing sets of static and HCF tests on CFRP and Fe-SMA strengthened steel plates and girders. Finally, a cost comparison is carried out for a specific case, where normal modulus (NM) CFRP plates and Fe-SMA strips were used for the prestressed strengthening of a real-scale steel I-girder. The cost analysis revealed that although the current price of Fe-SMA strips is higher than that of the NM CFRP plates, both of the strengthening systems are financially equivalent, when the achievable prestressing force and the cost of clamping systems are taken into consideration.

https://www.sciencedirect.com/science/article/abs/pii/S0950061819318434

Development of nail-anchor strengthening system with iron-based shape memory alloy (Fe-SMA) strips.

Fritsch, E., Izadi, M. and Ghafoori, E., Construction and Building Materials, 2019. 229: p. 117042.

This work discusses the development process of a direct fastening technique for strengthening steel members using iron-based shape memory alloy (Fe-SMA) strips. First, several lap-shear tests were performed to examine the efficiency of five nail-anchor systems in terms of load-carrying capacity, slippage, and convenience of installation. To this end, 3D optical digital image correlation (DIC) measurements (using an ARAMIS system) and numerical simulation were conducted. Different failure modes including tensile rupture of the strips, shear rupture of the nails, and/or sliding of the strips were observed and discussed. The optimum nail-anchor system was then determined. This system has a very short anchorage length of approximately 50 mm and only 12 nails (i.e., 3 × 4). Second, to demonstrate the efficiency of the proposed system, a steel I-beam was strengthened with the selected nail-anchor system and activated using an infrared heating (IRH) technique. The SMA-strengthened beam was subjected to static and then high-cycle fatigue loadings with a loading ratio of for 2.5 million cycles without any failure or damage, indicating reliable performance of the system. Owing to the larger coefficient of thermal expansion of the Fe-SMA material compared to that of steel, it was observed that a decrease and increase in the environmental temperature resulted in an increase and decrease of the pre-stress level in the Fe-SMA strip, respectively (i.e., an inverse correlation).

https://www.sciencedirect.com/science/article/abs/pii/S0950061819324845

Development of an iron-based shape memory alloy (Fe-SMA) strengthening system for steel plates.

Izadi M.R., Ghafoori E., Shahverdi M., Motavalli M. and Maalek S., Engineering Structures, 2018. 174: p. 433-446.

This paper presents the development of an iron-based shape memory alloy (Fe-SMA) system for the strengthening of steel plates. The shape memory effect (SME), which is the tendency of a deformed SMA to return to its original shape upon heating and subsequent cooling, was used in this study for prestressing steel plates. Five steel specimens were strengthened with different configurations (single-side, double-side, activated, and non-activated) of the Fe-SMA strips. A mechanical anchorage system was developed to anchor the prestressed Fe-SMA strips to the steel substrate. The SME in the Fe-SMA strips was then activated (i.e., the strips were prestressed) by heating to a temperature of approximately 260 °C using an electrical resistive heating technique. The test results showed that the achieved recovery stress of the Fe-SMA strips (i.e., the prestressing level after activation) was approximately in the range of 350–400 MPa, which led to a maximum compressive stress of −74 MPa in the steel plate. This compressive stress can be very beneficial and significantly increase the yield and fatigue strength of the steel plates. Finally, the strengthened specimens were subjected to static loading under a displacement-controlled condition up to failure. It was shown that the proposed strengthening technique eliminates the difficulties associated with conventional prestressing (e.g., by hydraulic jacks) and also offers a fast installation procedure as it does not require any surface preparation or curing for bond application.

https://www.sciencedirect.com/science/article/pii/S0141029618305030

Iron-based shape memory alloy for the fatigue strengthening of cracked steel plates: Effects of re-activations and loading frequencies.

Izadi M.R., Ghafoori E., Motavalli M. and Maalek S., Engineering Structures, 2018. 176: p. 953-967.

The paper discusses the application of an iron-based shape memory alloy (Fe-SMA) for the fatigue strengthening of steel plates. The shape memory effect (SME), which is the characteristic behavior of the Fe-SMAs, was used for the prestressed strengthening of steel plates. One steel plate without any pre-cracks and two steel plates with pre-cracks were retrofitted with Fe-SMA strips. The SMA-strengthened specimens along with a reference unstrengthened specimen were then subjected to high cycle fatigue (HCF) loading. The effect of multiple re-activations and different loading frequencies (e.g., fr = 0.005, 5, 10, and 15 Hz) on the HCF behavior of the Fe-SMA was investigated. The test results showed that the achieved prestressing level (i.e., recovery stress) in the Fe-SMAs for an activation temperature of 260 °C was in the range of 330–410 MPa, resulting in compressive stresses in the range of 35–72 MPa in the steel plates. Furthermore, it was observed that the recovery stress decreases slightly during cyclic loading, which should be considered in the design. The loss in the prestressing level was approximately 17–20% of the original prestressing; however, the re-activation (i.e., a second activation) process could retrieve a significant portion of the loss. The test results showed that the activated Fe-SMA strips could apply considerable compressive stresses to the cracked steel plate, which reduce the tensile stresses and stress intensity factors (SIFs) at the vicinity of the crack tip, resulting in a significant increase in the fatigue life of the specimens and a complete fatigue crack arrest in some cases.

https://www.sciencedirect.com/science/article/pii/S0141029618305042

https://www.sciencedirect.com/science/article/pii/S0264127517307311

Flexural strengthening of structural concrete with iron-based shape memory alloy strips.

Michels, J., Shahverdi, M. and Czaderski, C., Structural Concrete, 2017: p. 1-16.

This paper presents a study on structural concrete retrofitting with iron‐based shape memory alloys (Fe‐SMA). Initially, the Fe‐SMA strip is prestrained at ambient temperature with a remaining deformation. Subsequently, it is applied on the structure as an end‐anchored strip. The shape memory effect, characterized by the material’s back transformation to its initial shape, is created upon heating at an elevated temperature of about 160°C. In this case, a mechanical end anchorage refrains the alloy to develop its recovery in strain and hence transforms it to a recovery stress, which results in a prestress in the concrete substrate. The ease of installation of the strip itself combined with an efficient and rapid direct fastening method render this strengthening technique highly competitive for the market. In this paper, material characteristics such as the ductile behavior of the alloy in tension as well as its activation by means of fast resistive heating are presented. The application on reinforced concrete beams is described and static loading tests are shown in order to demonstrate the efficiency of the technique. An improved structural behavior at service state proves that Fe‐SMA strips are an efficient and innovative method for structural strengthening. Finally, a site application is presented. It demonstrates that Fe‐SMA strips are a competitive solution for replacing existing, more pricy, and technically more complicated methods.

https://onlinelibrary.wiley.com/doi/abs/10.1002/suco.201700120

Strengthening of RC beams by iron-based shape memory alloy bars embedded in a shotcrete layer.

Shahverdi, M., Czaderski, C., Annen, P. and Motavalli, M., Engineering Structures, 2016. 117: p. 263-273.

Shape memory alloys (SMAs) have the special property of returning to their initial shape upon heating which is called shape memory effect (SME). If the returning to the initial shape is prevented by a mechanical fixation, a prestress develops in the SMA due to the SME property. In the form of ribbed bars, the SMAs can therefore be used for the strengthening and stiffening of reinforced concrete (RC) structures. In particular, the recently developed iron-based shape memory alloy (Fe-SMA) with the composition of Fe–17Mn–5Si–10Cr–4Ni–1VC (mass-%) shows promising properties with regard to potential applications in civil engineering. In the framework of this paper, application of the recently developed ribbed Fe-SMA bars embedded in a shotcrete layer to strengthen RC structure is presented. Three beams were experimentally examined to demonstrate the application of this strengthening method. The flexural behaviors of the beams were investigated during activation and in a four-point bending loading test up to failure. Two of the beams were prestressed with ribbed Fe-SMA bars embedded in an additionally applied shotcrete layer. The third beam had normal steel reinforcement bars in the shotcrete layer and acted as the reference beam. The behavior at the serviceability stage was significantly improved by the prestressed Fe-SMA bars. The cracking load increased with this method compared with the reference beam. The results showed that the application of ribbed Fe-SMA bars embedded in a newly applied shotcrete layer on the bottom side of RC beams was successful and the strengthening technique worked well.

https://www.sciencedirect.com/science/article/pii/S0141029616300438

Iron-based shape memory alloys for prestressed near-surface mounted strengthening of reinforced concrete beams.

Shahverdi, M., Czaderski, C. and M. Motavalli, Construction and Building Materials, 2016. 112: p. 28-38.

Low-cost Fe-Mn-Si-based shape memory alloys (SMAs) have attracted much attention in the research community and in practice over the past two decades as a cost-effective alternative to the expensive Ni-Ti-based SMAs. The shape memory effect refers to the phenomenon in which SMAs, if they are deformed, return to their former shape upon heating. Near-surface mounted (NSM) strengthening techniques can be used to strengthen concrete beams. The advantages associated with NSM strengthening are its ability to significantly reduce the probability of harm that results from corrosion, fire, acts of vandalism, mechanical damage, and aging effects. Iron-based SMA (Fe-SMA) strips can be used as NSM reinforcements. The NSM Fe-SMAs can more easily be prestressed than NSM fiber reinforced polymers, because the prestressing of SMAs does not require any mechanical jacks and anchorheads.

In this study, an experimental program was established to investigate the flexural behavior of reinforced concrete (RC) beams that were strengthened and prestressed with Fe-SMA strips. The specific focus was on the demonstration of the feasibility of this strengthening technique. A total of six RC beams were experimentally examined under deflection control in a four-point bending loading rig. The experiments consisted of one beam strengthened by Fe-SMA strips but not prestressed, three beams strengthened by prestressed Fe-SMA strips, and one beam strengthened by one CFRP strip. Additionally, one beam with no strengthening, which served as the reference beam, was examined. The results showed that the cracking loads and mid-span deflections of prestressed beams compared to other beams were, respectively, higher and lower. Significant strengthening effects were achieved in NSM Fe-SMA-strengthened beams compared to the reference beam. These direct effects showed that the application of near-surface mounted Fe-SMA strips worked well as prestressing elements in concrete beams.

https://www.sciencedirect.com/science/article/abs/pii/S0950061816302355

Feasibility of iron-based shape memory alloy strips for prestressed strengthening of concrete structures.

Czaderski, C., Shahverdi, M., Brönnimann, R., Leinenbach, C. and Motavalli, M., Construction and Building Materials, 2014. 56(0): p. 94-105.

Near-surface mounted reinforcement (NSMR) is a strengthening method for concrete structures, such as buildings or bridges. NSMR involves strips or bars that are glued into grooves in the cover of the concrete. In this paper, a feasibility study is presented that uses iron-based shape memory alloy (Fe-SMA) strips instead of fiber-reinforced polymer (FRP) strips for NSMR. SMAs can more easily be prestressed than FRP. Because prestressing of SMAs does not require any mechanical jacks and anchor heads, the additional openings on the concrete surface beside the grooves that are needed to clamp the NSMR are significantly smaller.

The recovery stresses (i.e., the prestresses) were investigated in a tensile testing machine combined with a climate chamber. The temperature of the strips was increased up to 160 °C to provoke the phase transformation in the SMA. The bond behavior of the Fe-SMA strips glued into a groove with cement-based mortar was studied in lap-shear experiments using a 3D image-correlation measurement system. The result was compared with the bond behavior of CFRP strips glued with epoxy. Finally, two concrete bars with lengths of 70 cm were each reinforced with an Fe-SMA strip. After the concrete was cured, the Fe-SMA strips were activated (i.e., prestressed) by resistive heating, and the prestressing effect on the concrete bar was measured on the concrete surface using a mechanical strain gauge.

The study demonstrated the general feasibility of Fe-SMA strips in prestressed NSMR. The recovery stresses were in the range of 250–300 MPa. A sufficient bond behavior was observed. Concrete bars could be successfully prestressed with a centrally embedded Fe-SMA strip.

https://www.sciencedirect.com/science/article/abs/pii/S0950061814001032

Shape memory alloys for civil engineering structures – on the way from vision to reality.

Motavalli, M., Czaderski, C., Bergamini, A. and Janke, L., ACEE Journal, Architecture Civil Engineering Environment, The Silesian University of Technology, Poland, 2009. 2(4): p. 81-94.

Shape memory alloys (SMA) have been known for many decades. They are mainly used in medicine, electronics, air, and space industry and in the consumer goods industry. Examples are medical implants and instruments, cell phone antennas, frames for glasses, pipe couplings etc. The most usual SMA material on the market is nickel–titanium (Ni–Ti). Until today, SMAs have found very limited applications in civil engineering probably due to their cost and to limited knowledge of the material in the civil engineering industry. This paper presents existing applications, laboratory tests and new concepts of how to use shape memory alloys incorporated in energy dissipation devices, as well as for pre-stressing structures using SMA wires and for post stressing of existing structures using SMA tendons. Attempts to develop new generation of Iron based SMA for using in civil engineering structures will be presented as an alternative to existing high cost NiTi SMAs.

RC beam with variable stiffness and strength.

Czaderski, C., Hahnebach, B. and Motavalli, M., Construction and Building Materials, 2006. 20(9): p. 824-833.

Shape memory alloys (SMA) show a temperature depending stiffness and strength. A reinforced concrete (RC) beam with SMA wires was tested and compared with a conventional RC beam. Furthermore, tensile and pull-out tests with the SMA wires are presented. By using the constrained recovery effect, it was possible to produce a changeable prestress in the RC beam.

https://www.sciencedirect.com/science/article/abs/pii/S0950061805000796

Applications of shape memory alloys in civil engineering structures – Overview, limits and new ideas.

Janke, L., Czaderski, C., Motavalli, M. and Ruth, J., Materials and Structures, 2005. 38(279): p. 578-592.

Shape memory alloys (SMAs) are metallic materials with great potential to enhance civil engineering structures. They are often referred to as smart materials. A basic description of their highly non-linear material behaviour in terms of shape memory effect, superelasticity, martensite damping and variable stiffness is given in this article. It is followed by a brief introduction to Ni−Ti and Fe−Mn−Si SMAs. Pre-existing and new applications in the fields of damping, active vibration control and prestressing or posttensioning of structures with fibres and tendons are being reviewed with regard to civil engineering. Furthermore, the relatively high costs and the problem of retaining posttensioning forces when using some types of SMAs are named. In this regard is Fe−Mn−Si−Cr discussed as potential low cost SMA. A simple model for calculating the activation times of resistive heated SMA actuators or springs is presented. The results and measured data lead to further constrictions. Finally, new ideas for using SMAs in civil engineering structures are proposed in this article such as an improved concept for the active confinement of concrete members. This article is to introduce civil engineers to the world of shape memory alloys and invite them to contribute to their wider use in civil engineering structures.

| Konferenzen und Anderes |

- Iron based shape memory alloy strips, part 2: flexural strengthening of RC beams.

Michels J., et al. in SMAR 2017, Zurich, Switzerland, 13-15 September 2017. - Iron-based shape memory alloy strips, part 1: characterization and material behavior.

Shahverdi M., et al. in SMAR 2017, Zurich, Switzerland, 13-15 September 2017. - Behavior of Retrofitted Concrete Members Using Iron-Based Shape Memory Alloys.

Zerbe L., et al. in SMAR 2017, Zurich, Switzerland, 13-15 September 2017. - Stress recovery behavior of an Fe-Mn-Si-Cr-Ni-VC shape memory alloy subjected to high-cycle fatigue loading.

Ghafoori E., E. Hosseini, J. Michels. in SMAR 2017, Zurich, Switzerland, 13-15 September 2017. - Iron-based shape memory alloys (Fe-SMA) a new material for prestressing concrete structures.

Czaderski C., B. Weber., M. Shahverdi, M. Motavalli, C. Leinenbach, W. Lee, R. Brönnimann, and J. Michels.in SMAR 2015, Antalya, Turkey, 7-9 September 2015. - Strengthening of RC beams with iron-based shape memory alloy strips.

Shahverdi, M., C. Czaderski, and M. Motavalli. in SMAR 2015, Antalya, Turkey, 7-9 September 2015. - Thermomechanical characterization of an Fe-Mn-Si-Cr-Ni-VC shape memory alloy for application in prestressed concrete structures,

Lee, W.J., B. Weber, G. Feltrin, M. Motavalli, and C. Leinenbach, in Advances in Structural Engineering and Mechanics (ASEM13). 2013: Jeju, Korea, September 8-12, 2013. p. 544-552. - Application of shape memory alloys in civil engineering : past, present and future,

Motavalli, M., C. Czaderski, A. Bergamini, L. Janke, in ICCE-17. Honolulu, Hawaii, USA, July 26 – August 1, 2009. - Shape memory alloys for civil engineering structures – on the way from vision to reality.

Motavalli, M., C. Czaderski, A. Bergamini, and L. Janke. in Proceedings of AMCM’2008. Lodz, Poland, June 9-11, 2008. pp. 91-108. - Formgedächtnislegierungen im Bauwesen – eine Vision.

Czaderski, C. and M. Motavalli, SIA-tec21, 2003(19): pp. 10-13.

| Prüfberichte |

- memory®-steel – Material – und Tragwerksverhalten, Bemessung – vom Oktober 2018

- Bestimmung mechanischer Kennwerte an gerippten Betonstählen „re-bar“ bestehend aus einer Formgedächtnislegierung

– Kurzbericht vom Juli 2018 - Bestimmung mechanischer Kennwerte an gerippten Betonstählen „re-bar“ bestehend aus einer Formgedächtnislegierung

– Kurzbericht vom März 2017 - Activation and stress-relaxation of „memory-steel“ (Fe-SMA) of type „re-bar“ – Prüfbericht vom März 2017 bis Juni 2018

- Activation and stress-relaxation of „memory-steel“ (Fe-SMA) strips of type „re-plate“ – Prüfbericht vom Februar 2016